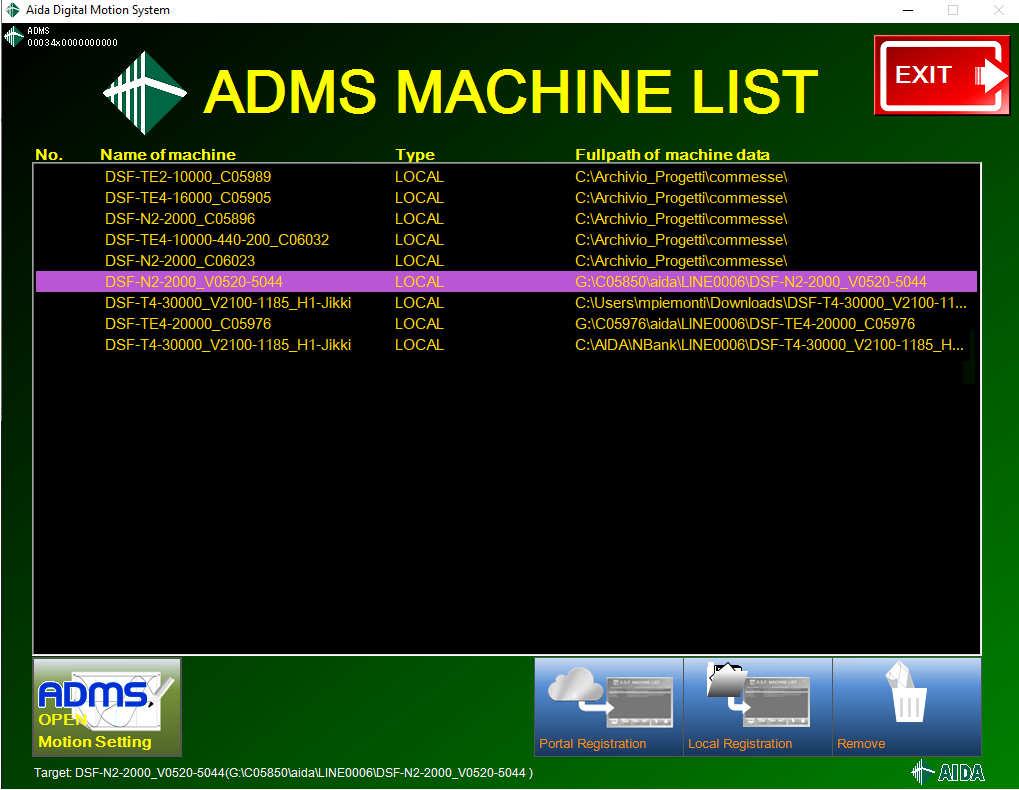

ADMS (AIDA Digital Motion System) is AIDA’s proprietary productivity tool developed to allow its customers to perform off-line press and transfer motion simulations.

ADMS allow customers to:

- set up new die production parameters off-line before moving the actual die into the press, avoiding to consume precious production time;

- optimise the exploitation of the transfer press and achieving maximum productivity

Main Features

- user-friendliness in removing potential collisions using die transfer interference curves defined by two points only;

- use of simplyfied 3D simulations allowing to run the software on the majority of notebooks (minimum system requirements apply);

- high degree of integration with the press and transfer control software enabling easily to move from off-line simulation environment to actual production environment;

- a single licence is required no matter how many AIDA transfer presses are predisposed and installed, even at different locations.

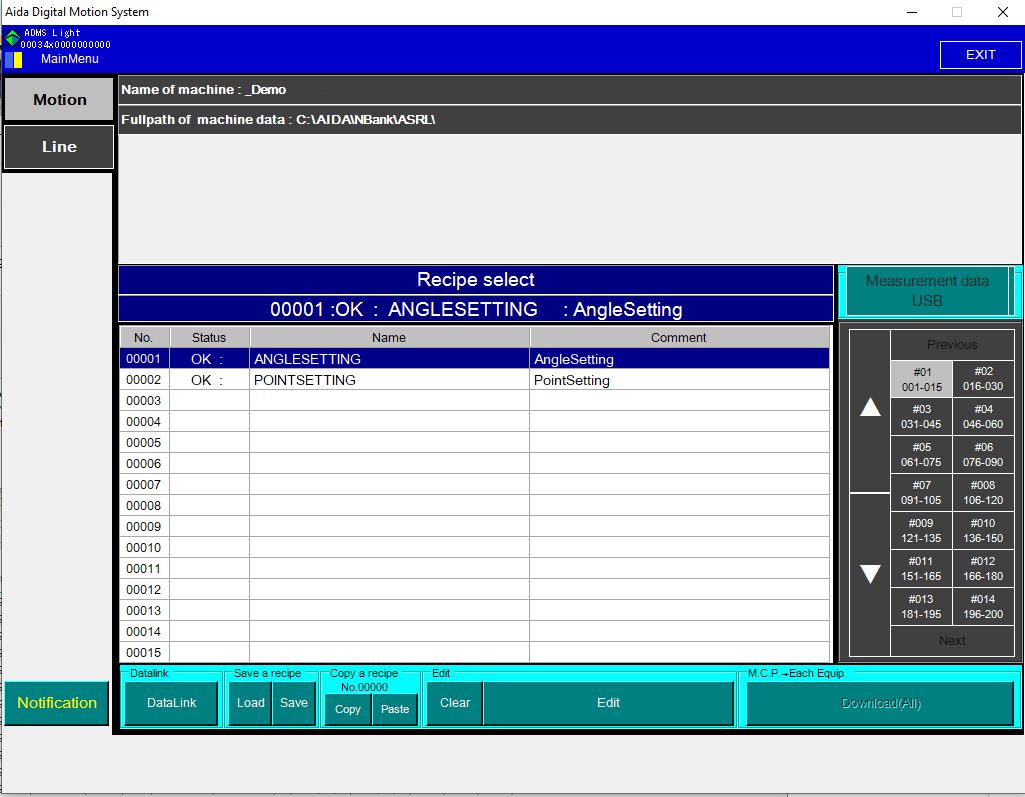

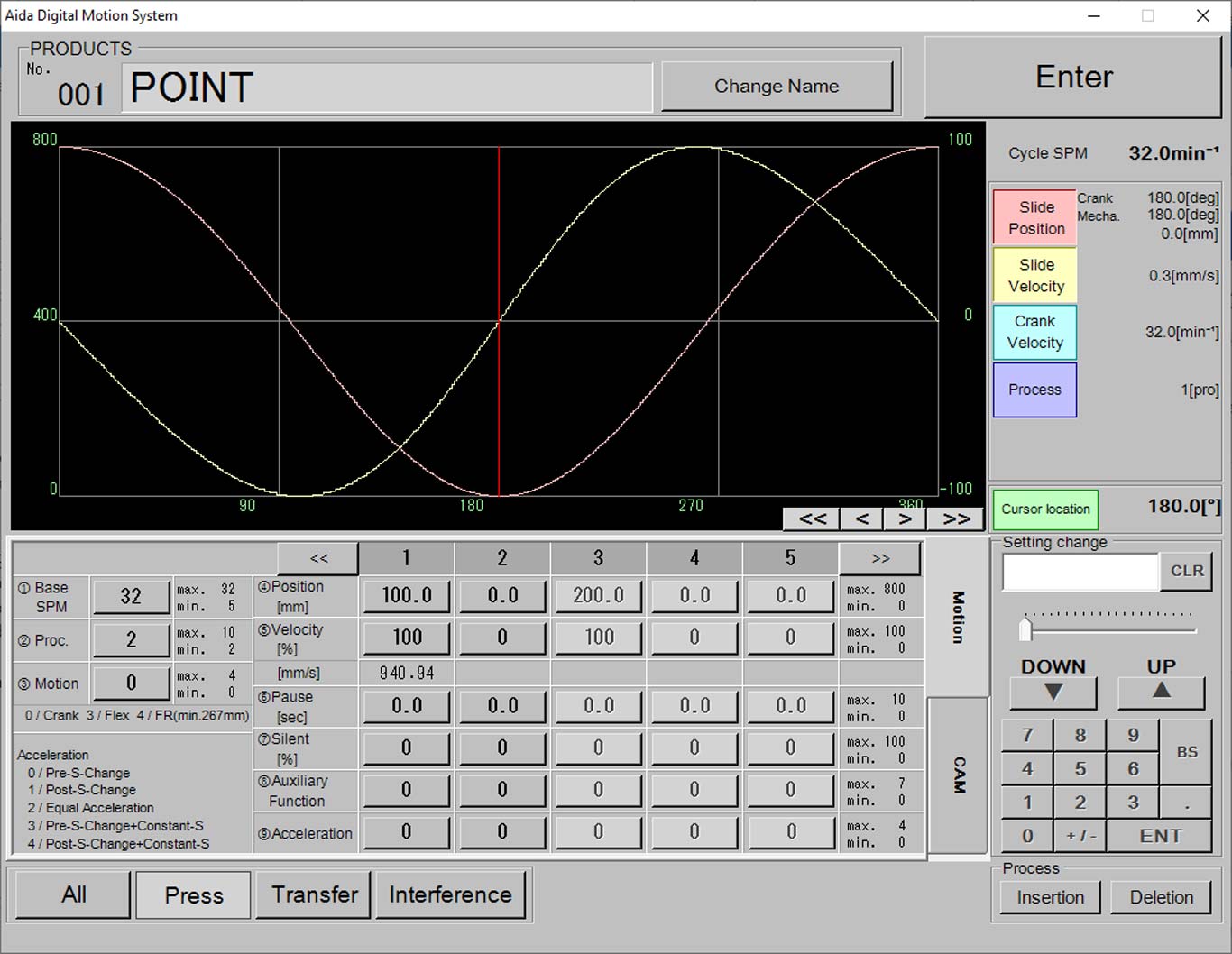

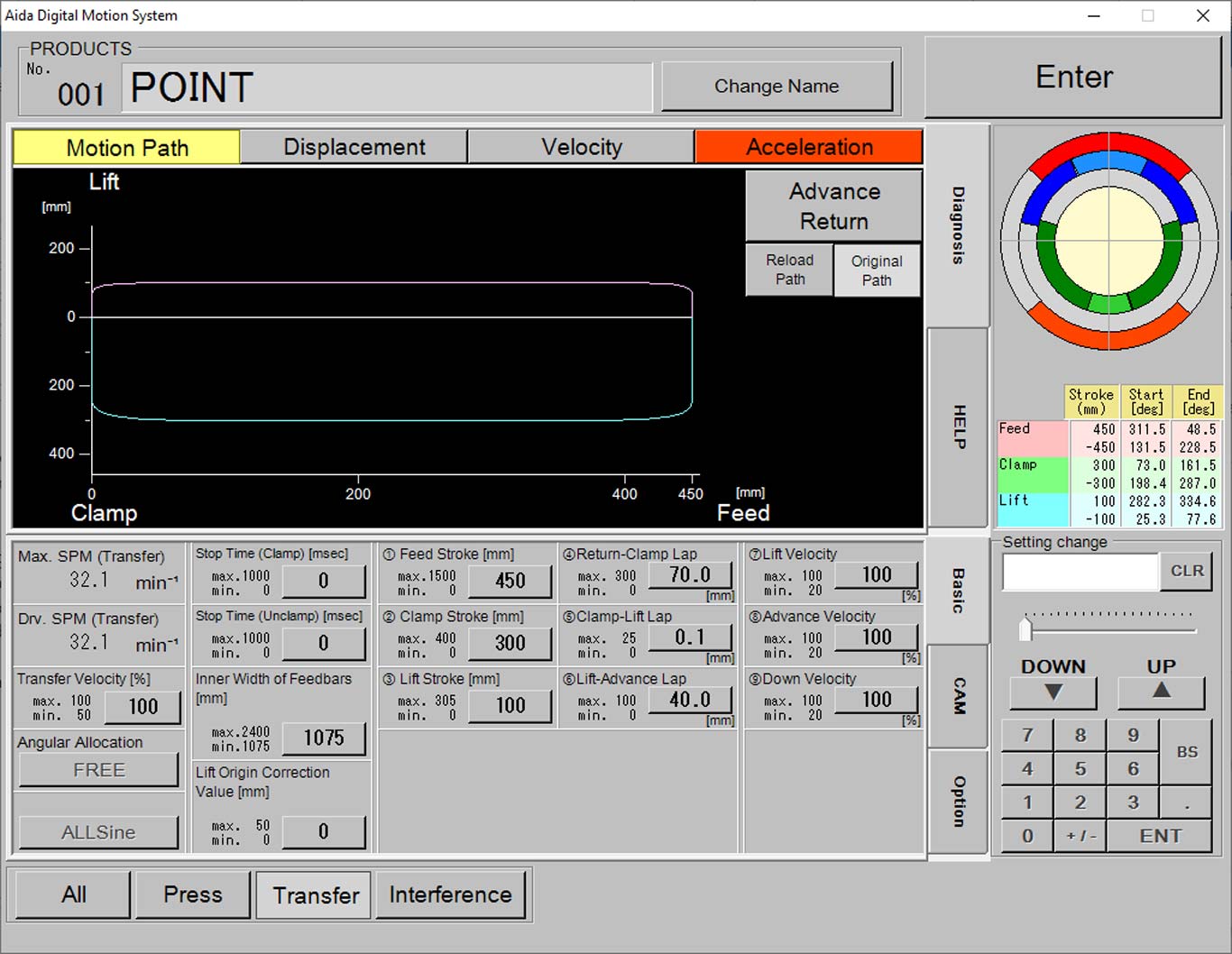

1. Press motion setting

By means of the interface the slide motion may be appropriately set to suit the specific part forming process.

By means of Flex motion setting mode it is possible to access a library of more than thirty pre-set motion profiles to build the specific overall motion profile: position, relevant speed, acceleration, time-lapse if necessary may be set.

By means of the graphic interface the slide speed and the production output are immediately displayed.

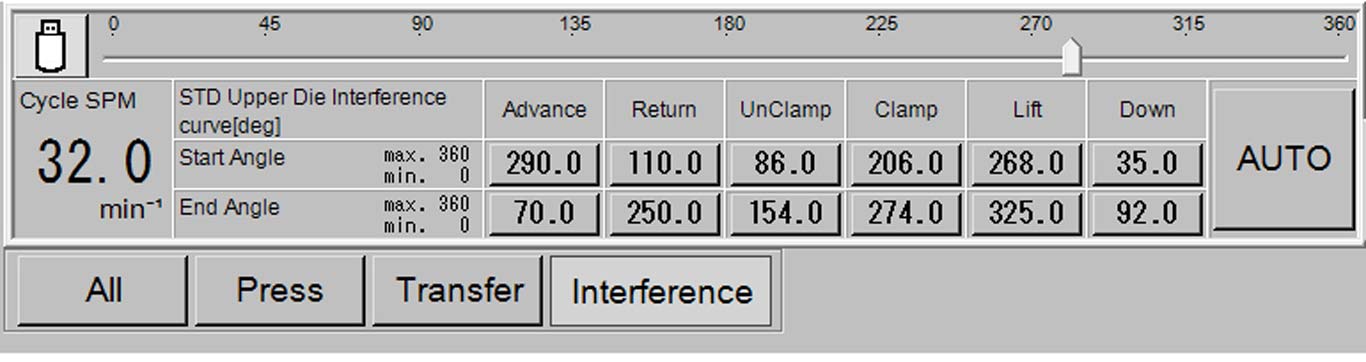

2. Transfer motion setting

By means of the interface it is possible to define all parameters relevant to the transfer motion (advance, lifting and closing steps) as well as overlapping of the movements.

Overlapping will allow to reach a more performant motion.

Starting and finishing angles would be automatically calculated.

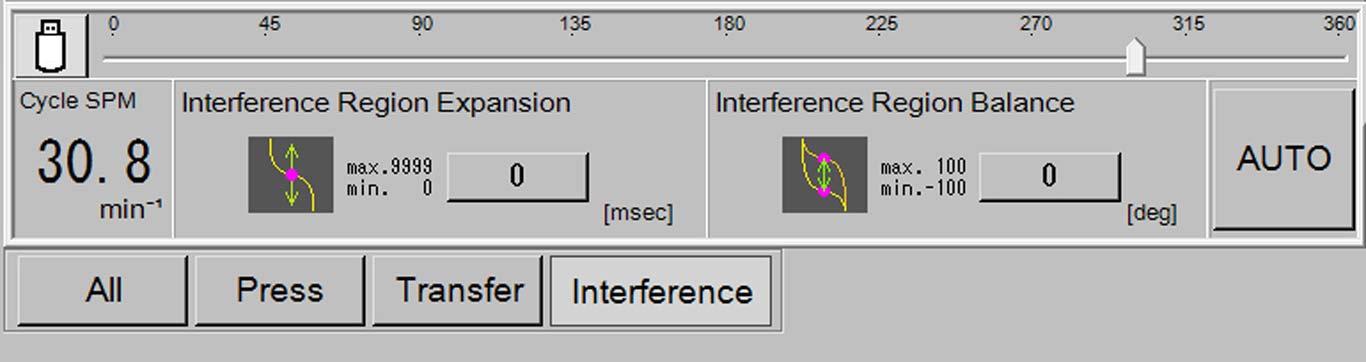

3. Press-transfer motion interface

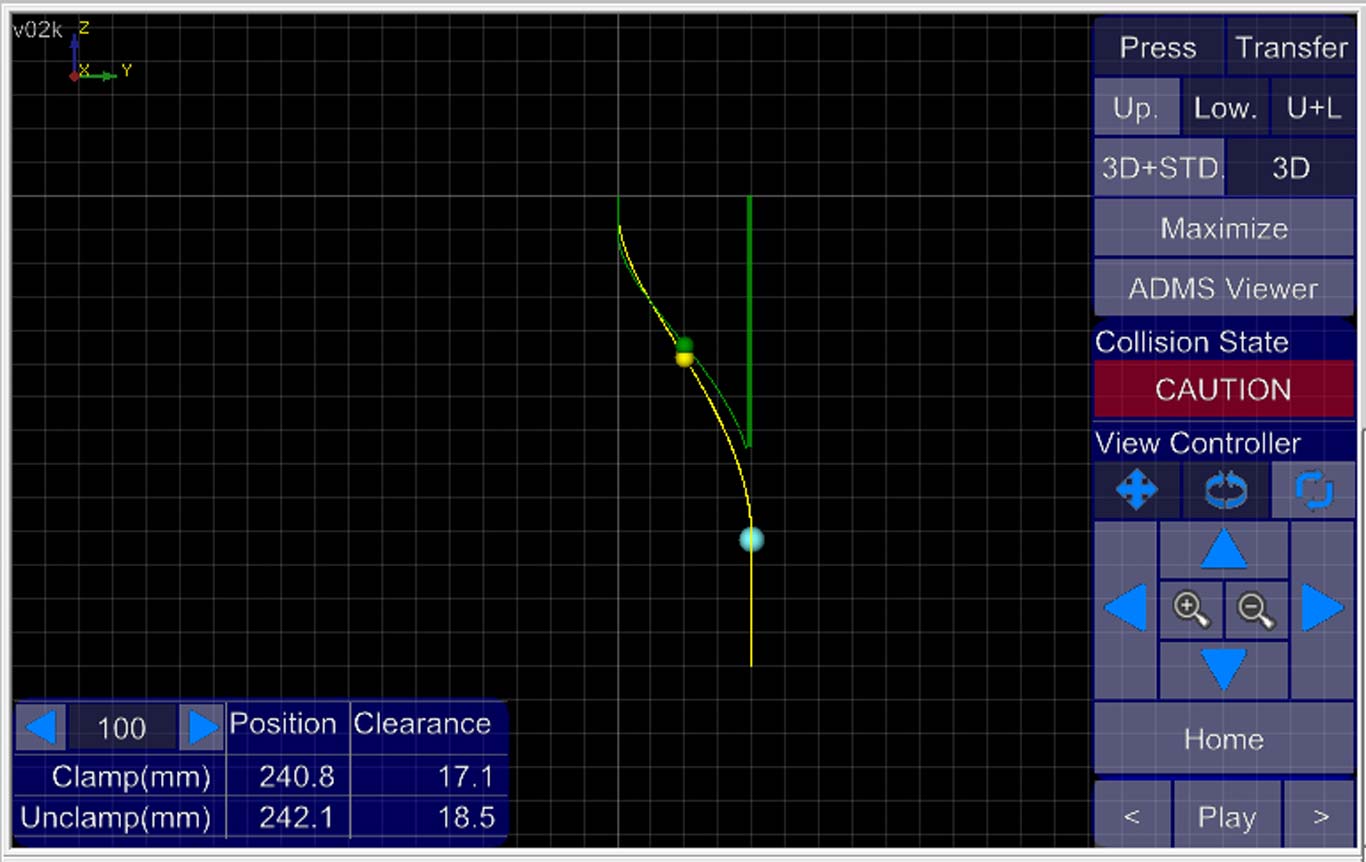

ADMS Light includes two levels of interference analysis.

Analysis based upon predefined die profile selecting from a library of ten possible die profiles. Whenever a collision is detected a CAUTION warning would be displayed.

By pressing the AUTO button the system itself will adjust the slide and transfer motions in order to avoid the collision, modifying the slide motion in the portion not engaging the part forming.

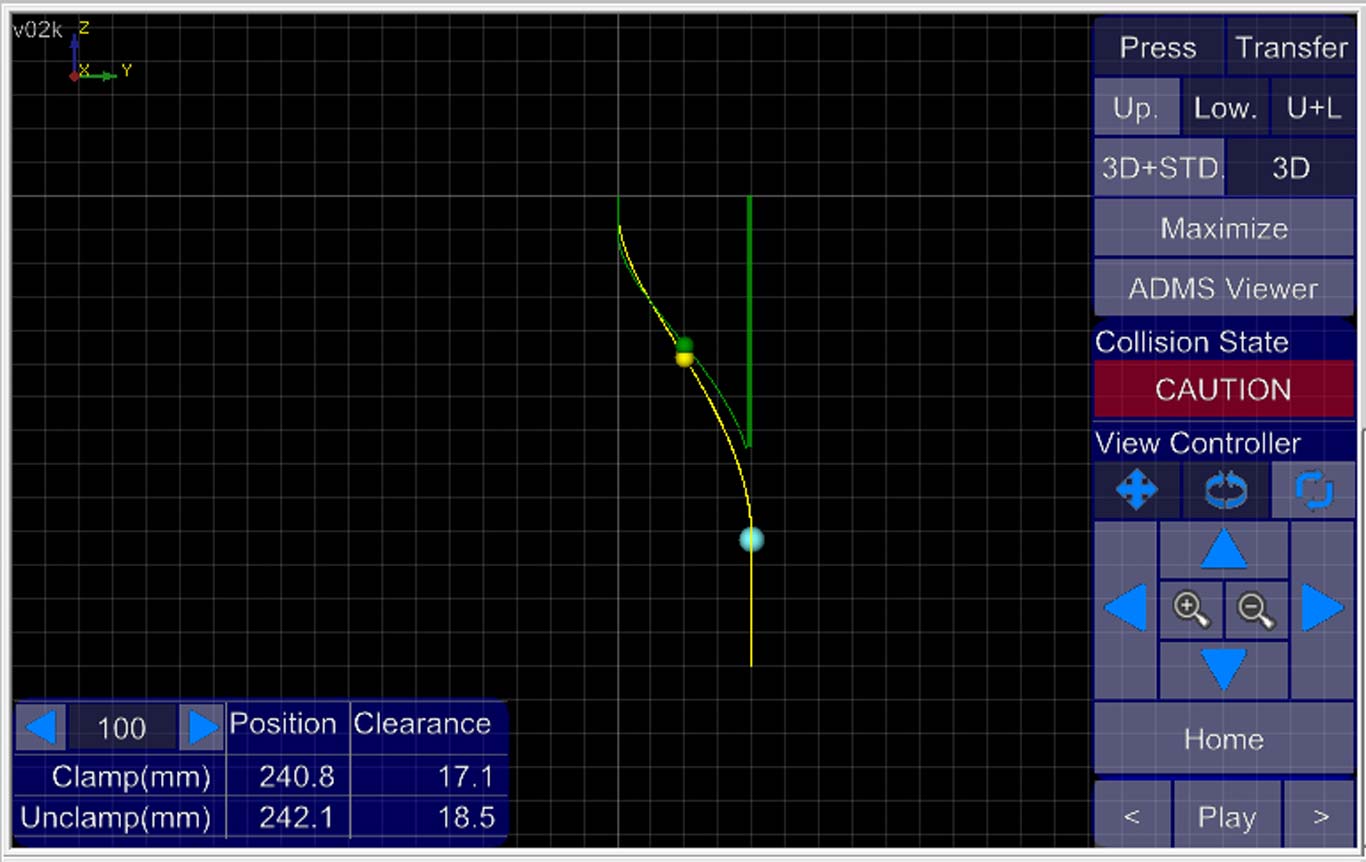

4. Base interference analysis

Analysis conducted defining the die profile by two points (green line).

The operator will have the opportunity to define two point (X and Y) green line based upon predefined die profile selecting from a library of ten possible die profiles.

Whenever a collision is detected a CAUTION warning would be displayed.

By pressing the AUTO button the system itself will adjust the slide and transfer motions in order to avoid the collision, modifying the slide motion in the portion not engaging the part forming.

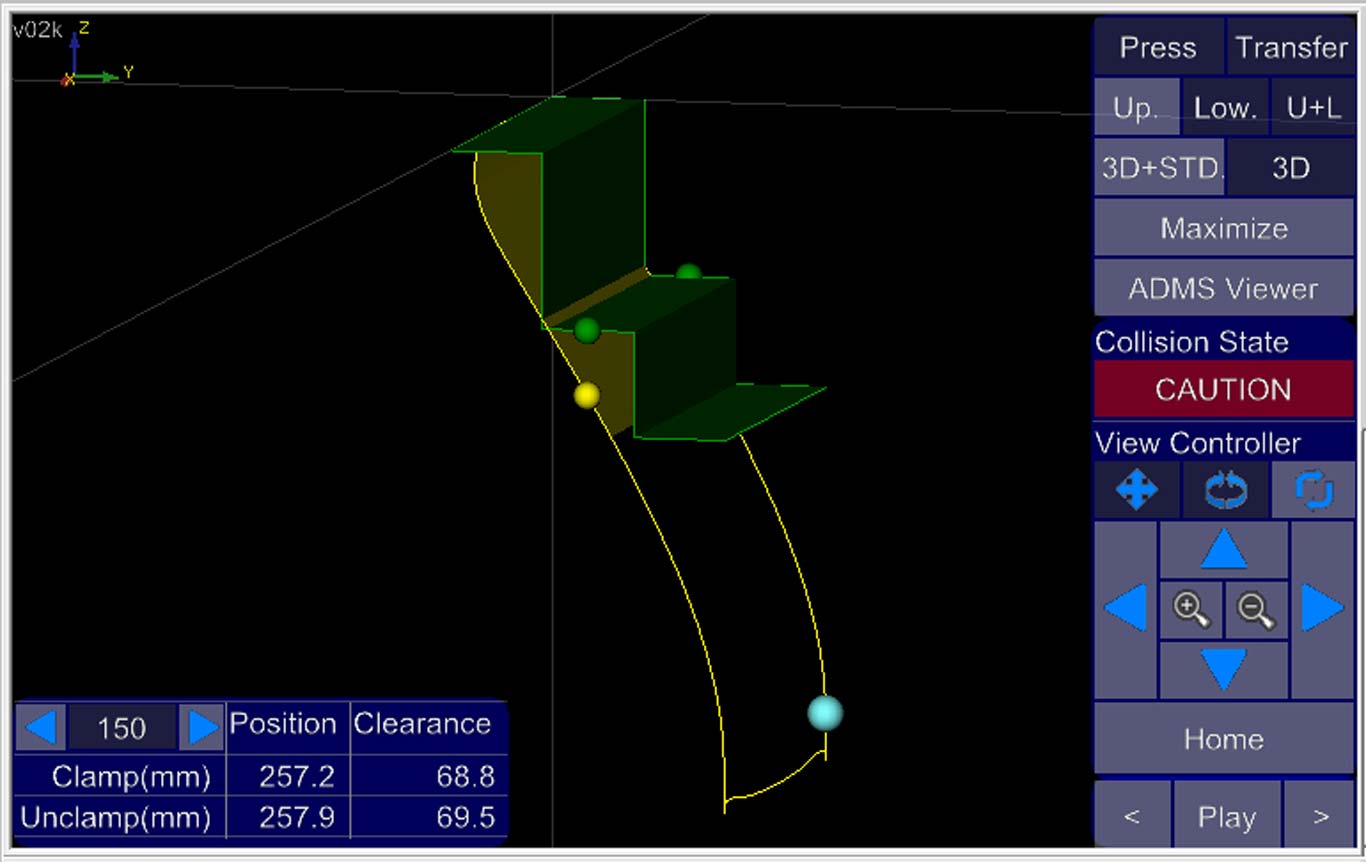

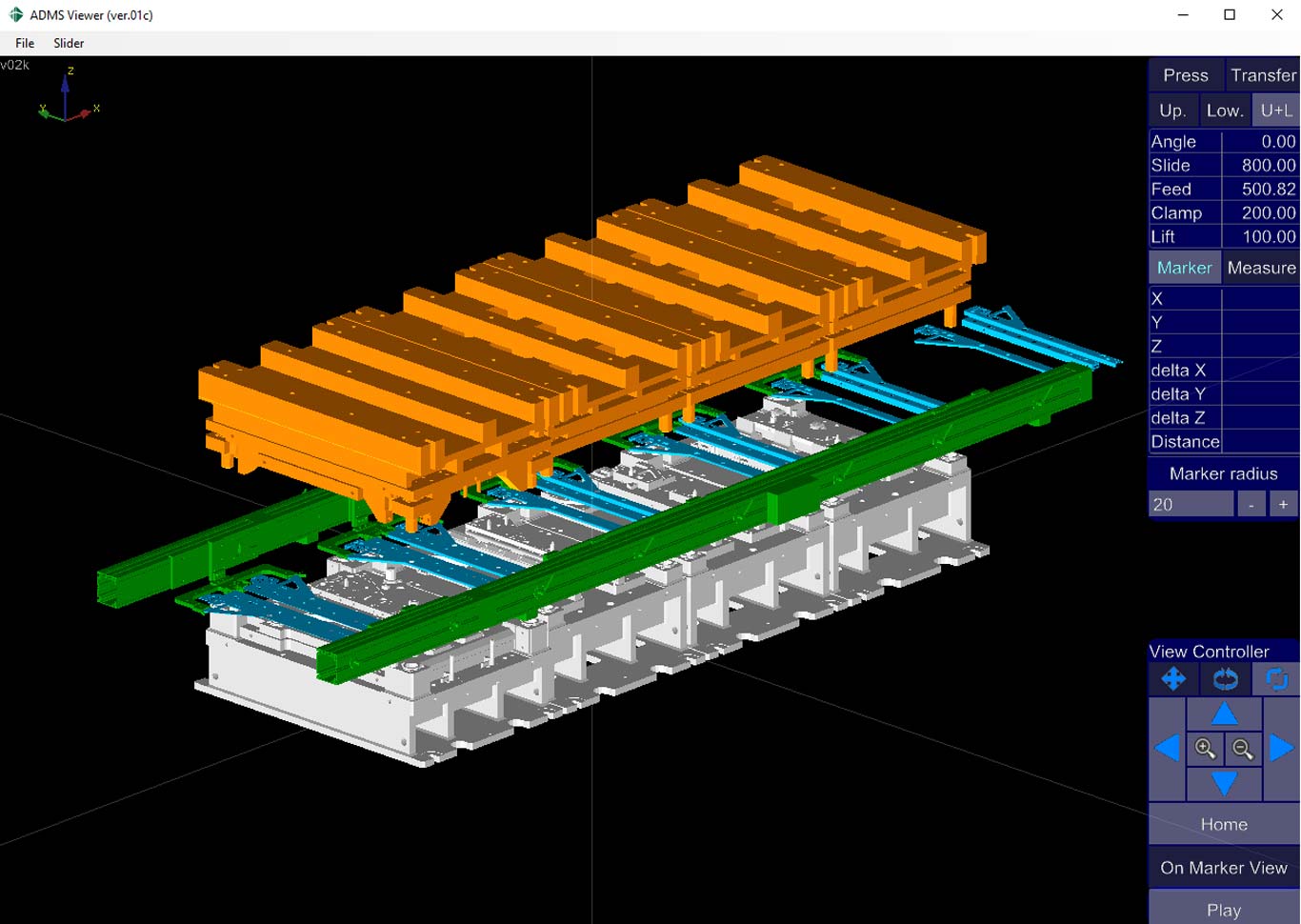

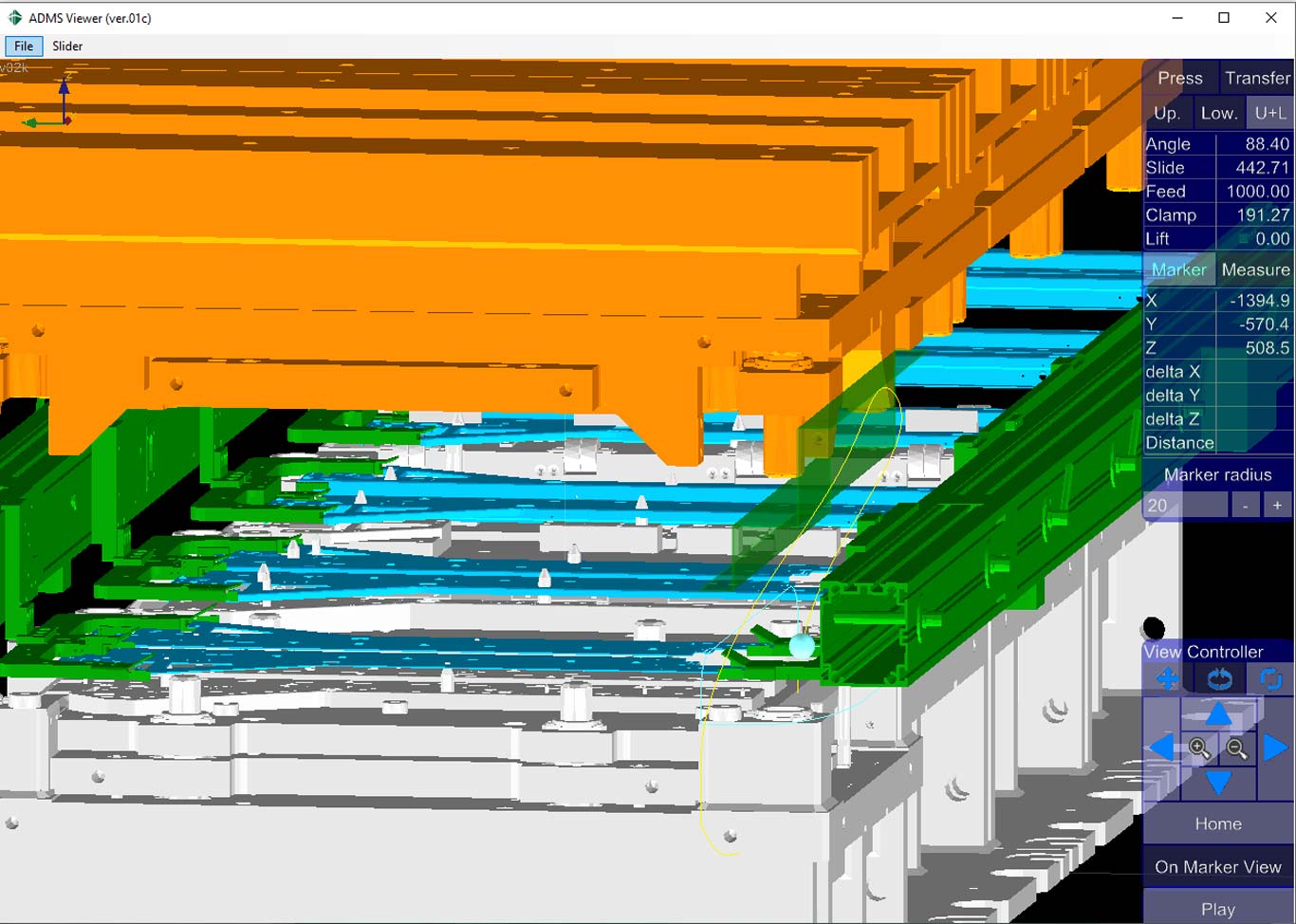

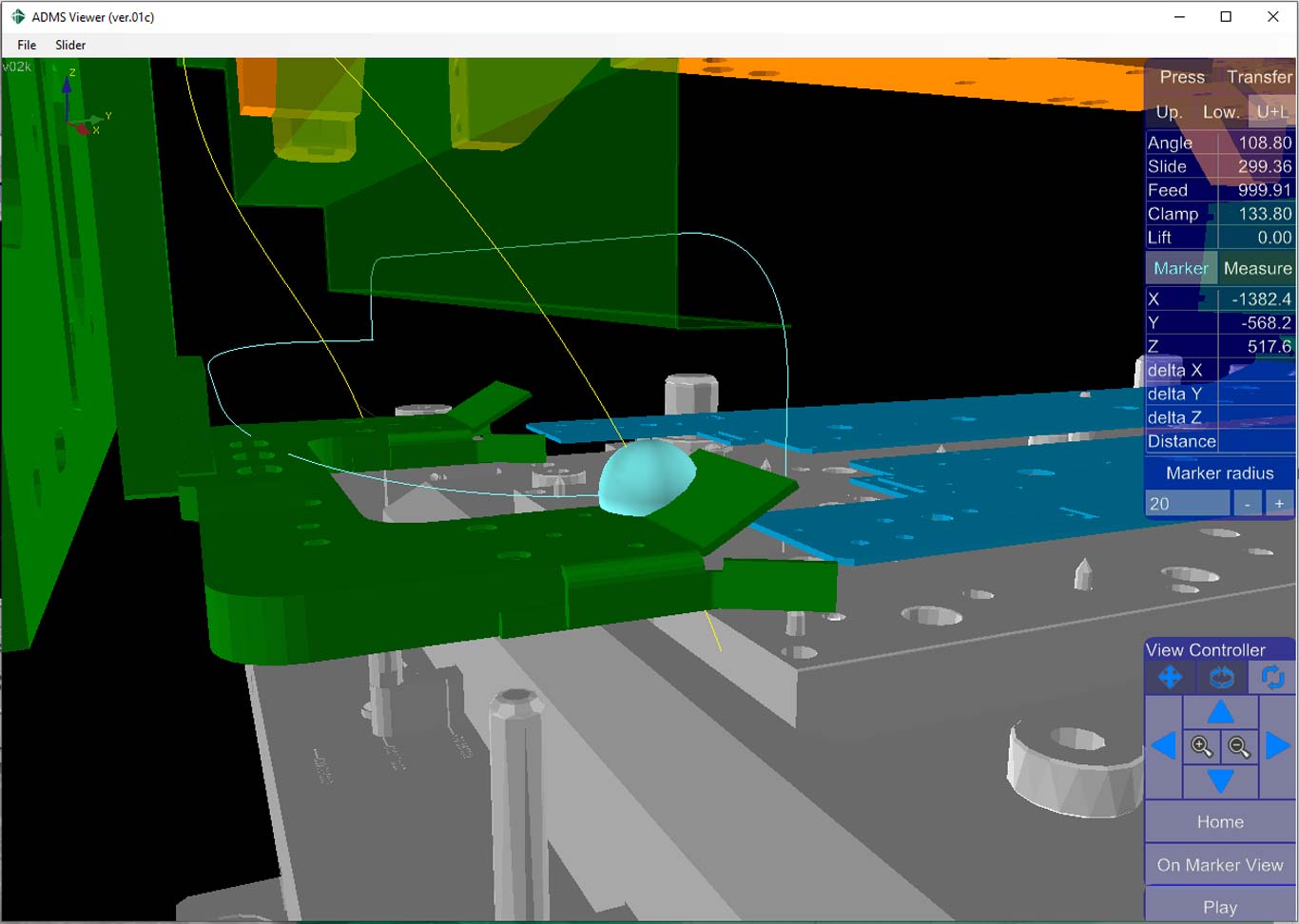

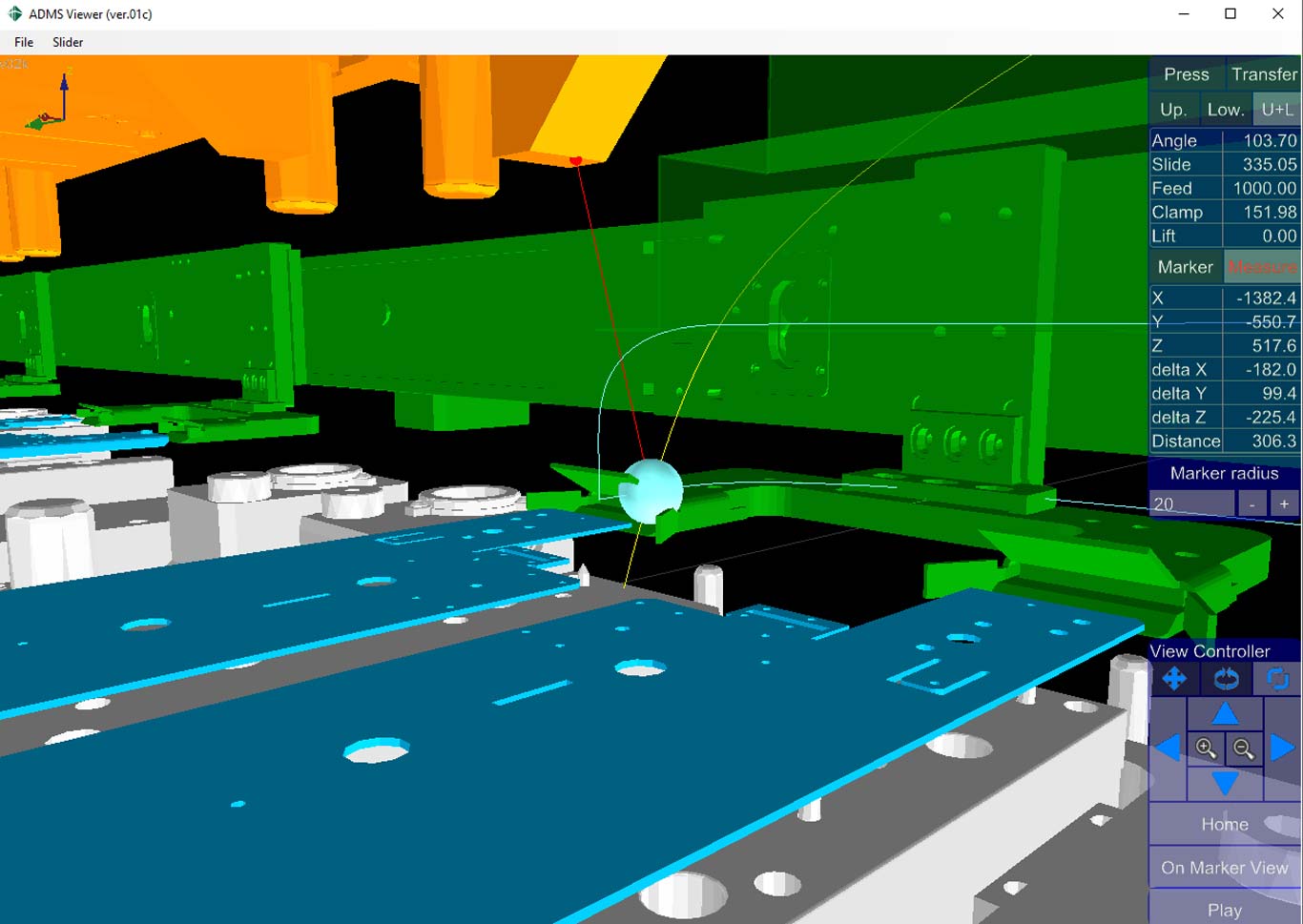

ADMS SE

ADMS more sophisticated version allowing full 3D interference analysis

Under this mode the analysis will be conducted using a simplified 3D model of the die (using a “step” file as an input).

Whenever a collision is detected a CAUTION warning would be displayed.

By pressing the PLAY button the collision point / area will be visually highlighted to the operator.

Contact AIDA

For more information or for any other request please do not hesitate to contact us.

Simply fill out the form on the side and you will be contacted shortly.