DON’T MISS OUT! REGISTER NOW

Explore AIDA’s advanced metalforming technology for bipolar plate forming. Be part of our exclusive event / REGISTER BY NOVEMBER 14TH TO SECURE YOUR SPOT!

REGISTRATION FORM

Complete the form below to confirm your attendance

AIDA is excited to invite you to the Bipolar Plate Day, taking place on December 4th, 2025 at our European Headquarters in Pavone del Mella (BS) – Italy.

We’re looking forward to welcoming you!

Join us for an exclusive overview of the new AIDA DSF-BE1 series of servo presses, expressly engineered to form bipolar plates.

See firsthand the results of the June 2025 die tests and enjoy a live BPP forming demo on the DSF-BE1-16000 servo press, showcasing the precision and reliability that set this series apart.

Bipolar Plate Day also includes a full plant tour, from fabrication to assembly department.

Be part of it – REGISTER BY NOVEMBER 14TH TO SECURE YOUR SPOT!

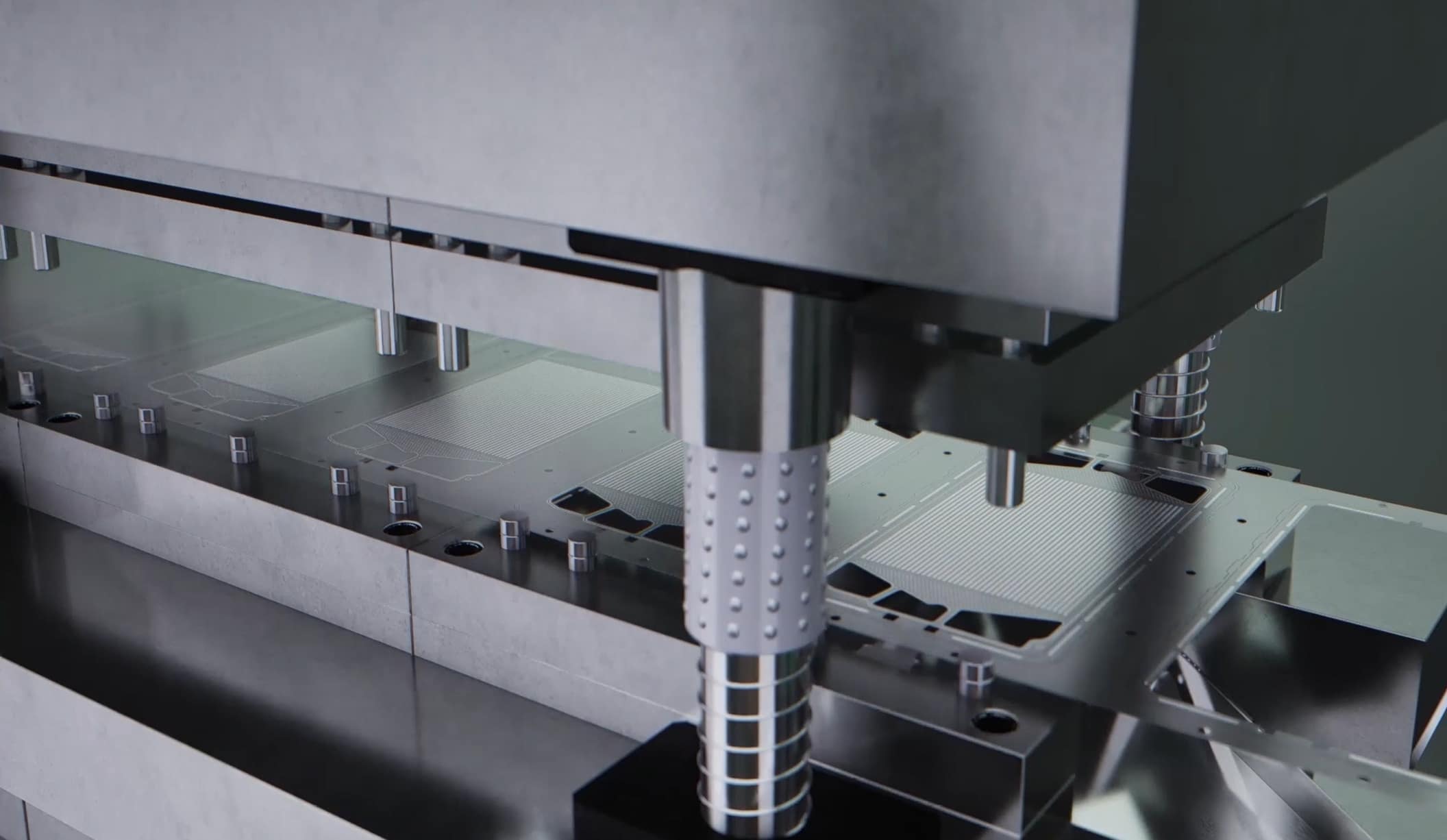

Fuel cells are the most efficient and environmentally friendly mean to generate electricity through the oxidation of hydrogen, being water vapor the only byproduct of this reaction. Fuel cells consist of bipolar plates stacked together to create an alternating sequence of anodes and cathodes. Given unique materials, specific geometry and required tolerances, their production demands a press with high rigidity and precision able to ensure consistent and repeatable processes.

Huge press force is required for precise groove forming. Forming load is concentrated in a small area at the center of the press bolster. High press rigidity is mandatory for achieving the required groove shape. Groove depth accuracy should be kept invariant during mass production avoiding heat generation in the press as groove depth variation in the active area will end up with low efficiency of electricity generation.

For this reason, press slide bottom dead center (BDC) should be kept stable during mass production. Native design solutions to improve press BDC position repeatability are a key success factor. Being material thickness of bipolar plates usually less than 0,1 mm clearance between punches and matrix edges needs to be in microns rang. This consequently leads to a demand for an extremely precise slide guiding system, to minimize wear and extend die life.

AIDA developed for the DSF-BE1 Series, designed for extreme applications, a special innovative composite steel welded frame structure offering unmatched rigidity. Additionally, the centered single-point design of the DSF-BE1 Series applies force precisely in the groove forming area, ensuring the required precision of stamped parts.

The DSF-BE1 presses are equipped with AIDA’s proprietary high torque, low revs and low inertia servo motors offering unmatched performance in metalforming applications. AIDA Ultra Low Clearance sliding guides significantly contribute to extend tools life even under severe loads distribution peculiar of bipolar plate forming process.The unmatched rigidity composite frame design is conceived to suit the most stringent rigidity and stability guidelines required by the specific bipolar plate forming process.